INNOVATION

How the Humble Chip Package Became an AI Power Play

AI demand is turning advanced packaging into the next big battleground in US chipmaking

12 Dec 2025

The less visible end of chipmaking is becoming a strategic priority for the US semiconductor industry as demand for artificial intelligence hardware surges. Advanced chip packaging, long treated as a routine final step, is now shaping performance, supply resilience and time to market for AI systems.

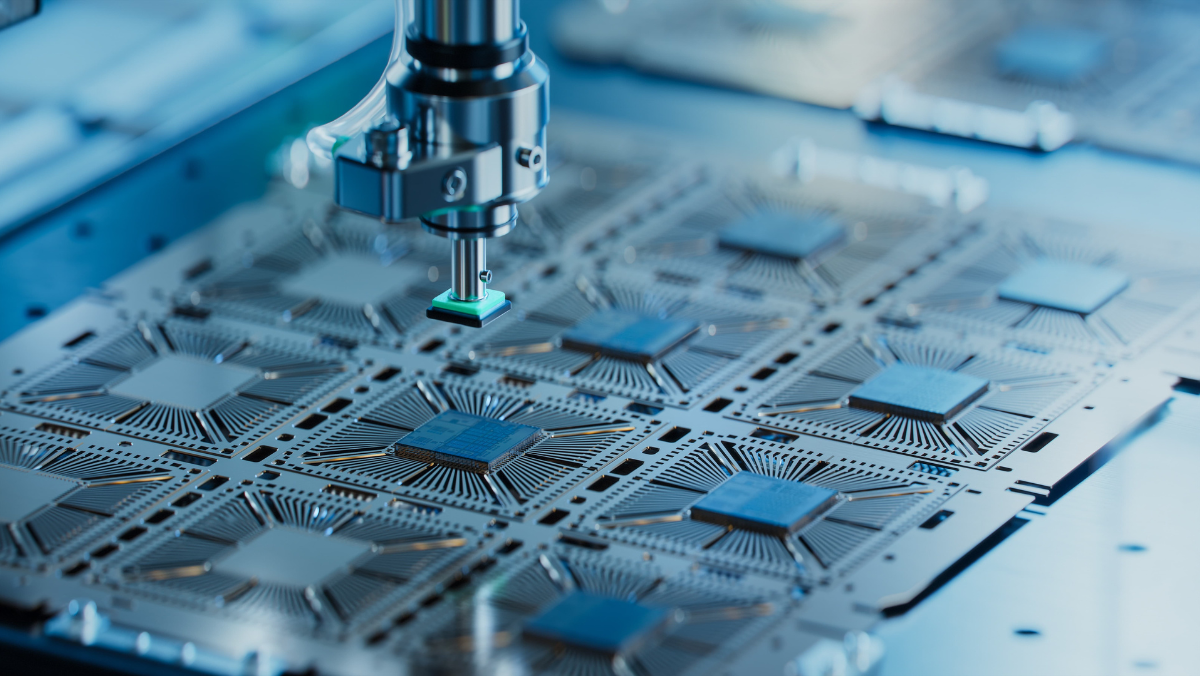

Recent investments to expand advanced packaging alongside US fabrication plants point to a change in industry focus. How chips are assembled determines data transfer speeds, power use and system efficiency. For AI accelerators and data centres, packaging has become as critical as the silicon itself.

A key driver is the spread of chiplet-based design. Instead of producing a single large processor, manufacturers increasingly link several smaller chips into one high-performance unit. The approach improves yields and design flexibility but relies on complex packaging techniques. Without enough capacity, even cutting-edge chips can be delayed after fabrication.

Industry reports suggest Taiwan Semiconductor Manufacturing Company is planning advanced packaging capacity near its US fabrication site, although the company has not confirmed a timeline. Analysts say the move would reflect strong customer demand and persistent bottlenecks in AI chip supply. Keeping more stages of production in one location can reduce delays, limit logistical risk and improve coordination across complex processes.

The effects are evident for AI chip designers such as Nvidia and AMD. Their products power large cloud data centres, where gains in performance depend heavily on how processors are linked with memory. Industry reporting has highlighted packaging constraints as a factor limiting AI chip output, even when fabrication capacity is available.

The shift comes as traditional performance gains from shrinking transistors slow. Engineers and executives increasingly see competition moving to system design and assembly. Advanced packaging is becoming a new area where companies seek an edge in AI hardware.

Scaling up remains difficult. Packaging plants are expensive to build and require specialised skills that are in short supply. At the same time, demand from AI, cloud computing and high-performance systems continues to rise.

The growing emphasis on packaging marks a broader change in the US chip strategy. By strengthening this often overlooked part of the supply chain, the industry aims to ease bottlenecks, improve reliability and support the next phase of AI-led growth.

Latest News

26 Feb 2026

Beneath the Surface of the CHIPS Act24 Feb 2026

Silicon Catalyst Expands Quantum Playbook16 Feb 2026

Can Cadence’s New Ecosystem Accelerate AI Silicon?13 Feb 2026

AI Digital Twins Race to Boost Chip Yields

Related News

REGULATORY

26 Feb 2026

Beneath the Surface of the CHIPS Act

PARTNERSHIPS

24 Feb 2026

Silicon Catalyst Expands Quantum Playbook

INSIGHTS

16 Feb 2026

Can Cadence’s New Ecosystem Accelerate AI Silicon?

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.